A modern fleet of instruments is available for various materials science studies, structural analysis, and the production of samples in the Materials Science Research Network of the Institute of Nuclear Research of the University of Debrecen. The nationally uniquely equipped laboratory was recognized by the National Office for Research, Development, and Innovation as the “Top 50 Research Infrastructure”.

The departments of materials science at the University of Debrecen and the Institute for Nuclear Research (Atomki) look back on decades of cooperation.

– We have been developing the laboratory together since the beginning because when the Institute of Physics moved to Bem Square, we could not place the electron microscopes here due to the mechanical and electrical noise caused by the electricity passing in front of the building, so Atomki provided us with space. We also started building our thin-film production equipment at Atomki, Csaba Cserháti, a professor in the Department of Solid State Physics at the Faculty of Science and Technology, recalled the beginnings.

Zoltán Erdélyi, head of the Department of Solid State Physics at the Faculty of Science and Technology, added that over the years, in cooperation with Atomki, the instrument park has been developed alternately according to the possibilities of the institutions. The modernization of the expanded laboratories in the meantime was given a major impetus by the Professor-led GINOP tender launched by the professor at the University of Debrecen and Atomki in 2017, which led to the development of materials science-industry cooperation base developed as a research center of excellence. next.

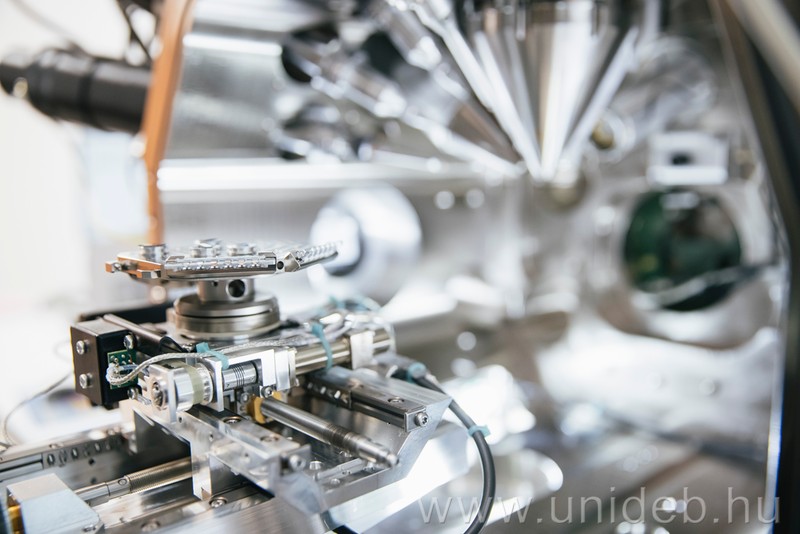

As part of the project, we purchased new instruments: a focused ion beam processing equipment – which can be used to “carve” materials on an atomic scale, a Raman-AFM microscope suitable for surface examination, and a spectroscopic ellipsometer. We replaced the previous, obsolete X-ray diffraction equipment for thin-film examination and made our transmission electron microscope suitable for analytical examinations.

– Zoltán Erdélyi, head of the department, listed the developments implemented within the framework of the four-year tender.

The professor emphasized that the instrument set provides a unique opportunity for the production and testing of (nano) structures for research and development purposes, performs educational tasks in connection with the University of Debrecen, and provides research, development, and innovation support to international manufacturing companies to solve manufacturing technology problems.

A coherent set of instruments has been created that is unique in Central and Eastern Europe, enabling nanotechnology-level analysis and construction at the atomic layer thickness. As an open-access regional center, it attracts domestic and international cooperating partners.

Our laboratories offer a wide range of thin-film production options for users, such as magnetron sputtering, thermal and plasma-assisted atomic layer deposition (ALD, PE-ALD), and evaporation. A series of furnaces provide heat treatment of the samples to be tested in different atmospheres and vacuum (HV, UHV) to study the thermal stability of thin films, layer systems, atomic motion processes, or the formation dynamics of different phases. Micro- and nanoscale sampling is provided by equipment such as scanning electron microscopes (SEMs), one of which is equipped with a focused ion beam processing equipment (FIB / SEM), including a transmission electron microscope (TEM) suitable for atomic and nanoscale structures. Raman microscope combined with a nuclear force microscope, a spectroscopic ellipsometer, or a combined device capable of analyzing samples in a common vacuum system using secondary neutral mass spectrometry (SNMS), X-ray photoelectron spectroscopy (XPS), low energy ion (LEPS) by contact force microscopy (nc-AFM). A modern thin-film X-ray machine is also available for structural analysis of the samples. Although our field of research focuses largely on nanotechnology, our instrumentation and knowledge base are also prepared to solve the problems of classical materials science, explained Professor Zoltán Erdélyi.

The head of the department expressed the hope that more and more industrial companies in the region will recognize the opportunities inherent in the Materials Science Research Network and will visit the laboratories with their production technology problems and development tasks.

hirek.unideb.hu