The education of the first group of students specializing in vehicle manufacturing in the vehicle engineering bachelor’s program of the University of Debrecen Faculty of Engineering at the Debrecen Training Center of the BMW Group Factory has been completed. Among other things, the participants learned about planning, cutting, sheet metal working, and the disassembly and assembly of parts.

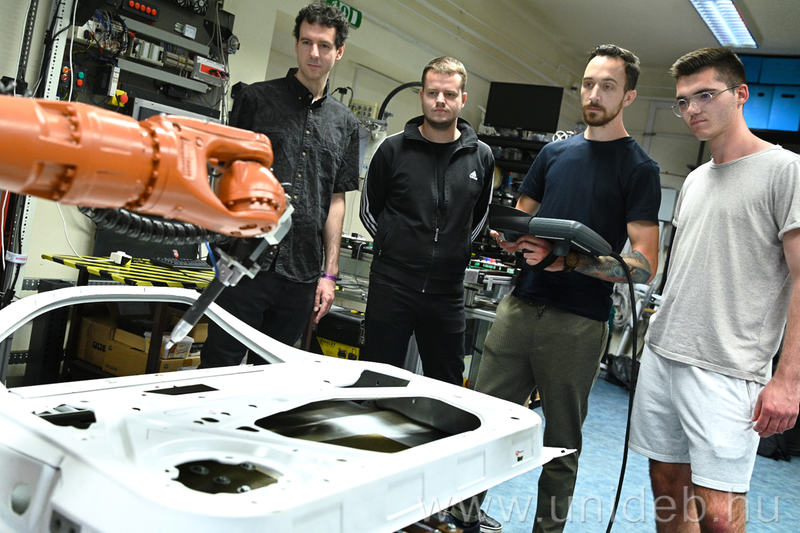

33 students of the BSc vehicle engineering course at the Faculty of Engineering of the University of Debrecen participated in a total of 16 hours of practical training in the recently completed BMW Training Center in Debrecen for 4 weeks within the framework of the vehicle production II subject.

In accordance with the educational program of the German car manufacturer, the students learned metal industry practice and automotive knowledge. Among other things, they got to know electronics, 3D printing, and automation

– said Sándor Bodzás, deputy head of the Department of Mechanical Engineering.

He added that many changes were made to the vehicle engineering training to be able to meet the needs of the companies.

For example, we place greater emphasis on the presentation of industrial production line simulations, 3D CAD design, and 3D printing technologies. Vehicle engineering students have more hours than before in the Vehicle Manufacturing Laboratory, where machines used in the automotive industry are also programmed in practice

– István Erdei Timotei, a teaching assistant at the Department of Automotive Engineering at the Faculty of Engineering explained the details.

He explained: that the teachers of the Department of Automotive Engineering also continuously expand their knowledge by obtaining additional certificates and participating in company training courses. According to the experience of the Faculty of Engineering, ever since BMW announced that it would build its newest car factory in Debrecen, interest in the Faculty of Engineering’s vehicle engineering training has grown by leaps and bounds.

(unideb.hu)